4 products

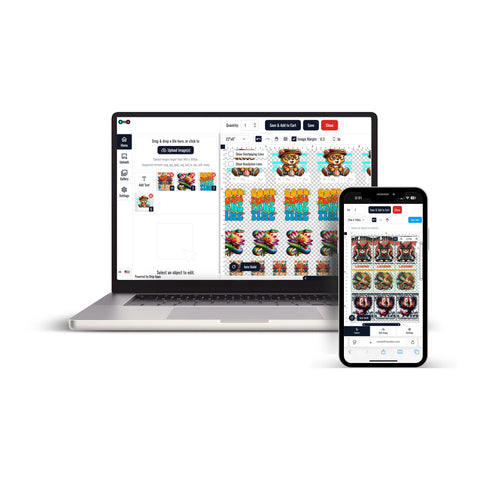

Revolutionizing Custom Printing

DTF heat transfers are a versatile and efficient solution for applying vibrant, durable designs to many fabric types. This modern printing method has quickly become popular among apparel brands, small businesses, and DIY creators due to its flexibility and professional results. These transfers deliver impressive print quality, excellent color accuracy, and long-lasting durability even after repeated washing. This guide explains essential equipment, techniques, and best practices to help achieve consistent, professional transfers for a wide range of projects.

What Are Direct to Film Heat Transfers?

Direct to Film heat transfers use a modern printing process where designs are printed onto a special PET film and then applied to fabric using heat and pressure. Unlike traditional methods, DTF heat transfers do not require cutting or weeding, making the process faster and more efficient.

This method provides multiple advantages for custom printing projects of all sizes.

Vivid Colors: Creates bright, long-lasting designs with fine detail and strong opacity.

Versatility: Performs well on cotton, polyester, blends, and even performance fabrics.

Ease of Use: Requires less preparation and setup compared to traditional screen printing.

Because of these benefits, DTF heat transfers are ideal for custom apparel, branding, and short-run production.

Heat Press for DTF Heat Transfers

A heat press designed for Direct to Film use ensures even heat and pressure across the entire design. This consistency is essential for producing durable and high-quality DTF heat transfers that adhere properly to the fabric.

Using the right heat press helps reduce errors such as incomplete bonding, peeling edges, or uneven finishes.

Key Features

Adjustable Temperature and Pressure: Enables precise control for different fabric types and transfer materials.

Large Heat Plate: Accommodates various design sizes, including oversized prints and back designs.

Consistent Heat Distribution: Reduces uneven transfers and increases the lifespan of the final print.

How to Heat Press DTF Transfer

Step-by-Step Process

Applying DTF heat transfers correctly requires attention at every stage to achieve optimal results and long-term durability.

Prepare the Fabric: Ensure the fabric is clean, dry, and wrinkle-free to avoid imperfections.

Position the Transfer Film: Place the film design-side down on the fabric surface.

Set the Heat Press: Use recommended settings of 300–325°F for 10–15 seconds.

Press the Transfer: Apply medium to firm, even pressure across the entire design.

Peel the Film: Allow the transfer to cool slightly, then peel carefully.

Final Press (Optional): Press again for 5–10 seconds to enhance durability and softness.

DTF Heat Transfer Printer

A printer designed specifically for Direct to Film printing improves accuracy, color consistency, and overall production efficiency. These printers are engineered to handle white ink and specialized DTF inks.

Important Features

High Resolution: Produces sharp details, smooth gradients, and clean text edges.

Wide Compatibility: Supports multiple film types and ink formulations.

Durability: Suitable for continuous operation in both small shops and high-volume environments.

Ready to Press Direct to Film Transfers

Ready to press Direct to Film transfers remove the printing step entirely, allowing users to focus only on application. These transfers are ideal for businesses that want speed and consistency without investing in printing equipment.

Advantages

Time-Saving: Speeds up workflow by eliminating printing and curing steps.

Consistent Quality: Professionally produced transfers ensure repeatable results.

Beginner-Friendly: Ideal for users new to DTF heat transfer or home-based setups.

DTF Transfer Heat Press Settings

Correct heat press settings are critical for successful transfers and long-lasting prints. Settings may vary slightly depending on fabric and film type.

Recommended Settings

Temperature: 300–325°F

Time: 10–15 seconds

Pressure: Medium to firm

Helpful Tips

Always test on scrap fabric before production. Adjust heat and pressure as needed to prevent scorching or incomplete adhesion.

Applying Transfers with Cricut Heat Press

The Cricut Heat Press is commonly used for small-scale DTF heat transfer projects due to its portability and ease of use. While it is not industrial-grade, it works well for hobbyists and small businesses.

Application Steps

Set the Temperature: Adjust the Cricut app to 315°F.

Place the Transfer Film: Align carefully on the fabric surface.

Apply Heat: Press firmly for 15 seconds.

Cool and Peel: Allow cooling, then peel slowly for best results.

DTF vs Heat Transfer Methods

Understanding the difference between and traditional heat transfer methods helps determine the best solution for your production needs.

| Feature | DTF Heat Transfer | Traditional Heat Transfer |

|---|---|---|

| Fabric Compatibility | Works on all fabrics | Limited options |

| Durability | High | Moderate |

| Setup Time | Quick | Longer |

| Cost Efficiency | Ideal for small runs | Better for bulk |

These links lead to the social profiles for custom printing service specializing in DTF (Direct-to-Film) transfers. You can view their creative work and connect with them on TikTok for video content, Instagram for images and updates, and Facebook for community engagement and business information.