4 products

What Is UV Transfer?

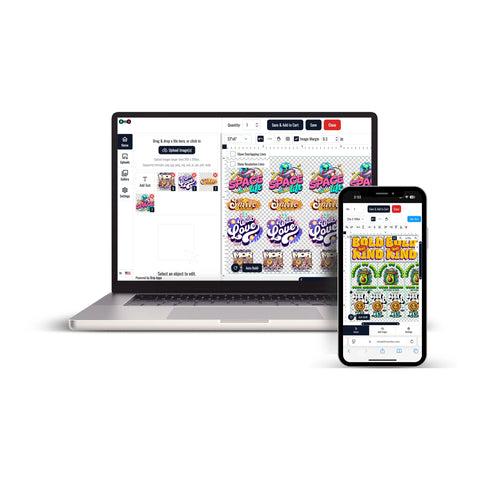

UV Transfer is an advanced printing technique that creates vivid and durable images. It uses ultraviolet light to cure special inks the instant they touch the surface. With each flash of UV, you get crisp detail and strong, bold colors. The system has gained attention for use in making custom items, adding logos, and bringing premium aesthetics to packages and products.

Understanding the Modern Printing Process

This process starts with your design being printed onto a transfer film with UV-curable inks. The ink solidifies when exposed to ultraviolet lamps, forming a sturdy and colorful image. Using heat or adhesives, the design moves from film to the target surface. Finished prints become waterproof, scratch-resistant, and exceptionally long-lasting. Because curing is immediate, no time is wasted on drying. That keeps your environment cleaner and production flows much faster compared to traditional printing.

Why Choose This Innovative Printing Technique?

This technology allows for broad creative freedom across a range of projects. You get detailed, high-resolution prints with high adhesion to many surfaces. The final products resist fading and cracking, which matters for lasting branding or retail items. Efficiency is another strength, as you use less time and material and reduce unnecessary waste.

Key Benefits for Various Applications

- Rapid Curing: Ultraviolet lamps instantly cure the ink, speeding up production.

- Lasting Durability: Prints resist water, scratches, and color loss, giving them a longer life span.

- Sharp Imaging: Each print offers defined lines, clear text, and powerful colors.

- Eco-Friendly: Inks hold lower levels of volatile organic compounds, minimizing the environmental impact.

- Material Versatility: This approach works on plastic, wood, glass, ceramics, metals, and more.

Substrate Compatibility and Printing Applications

The system's flexibility extends to a diverse range of surfaces. No matter if you're working with glass, metal, plastic, wood, or ceramics, finished images remain sharp and colorful. Businesses use this approach for creating custom goods, making shop signage, unique branding, and upgraded packaging for presentation.

Common Uses for Customization

- Designing custom phone cases and personal accessories

- Printing product labels and branded packaging inserts

- Producing unique plaques and commercial signage

- Enhancing glassware, bottles, and home décor pieces

- Making high-end corporate gifts and personalized promotional items

For many small businesses, this method keeps project costs manageable. It lets them handle projects in-house while maintaining professional quality on every order.

UV Transfer vs. Older Printing Methods

When compared with traditional printing methods—such as screen printing—the UV Transfer process stands out for speed and results. Colors fix in seconds, cutting the chances of smudging or undesired blending. This advanced technique reduces waste and helps businesses use less energy. Previous approaches usually need higher heat and extra steps. Now, production is faster and the workflow simpler, leading to quicker project turnaround.

Tips for Outstanding Printing Results

- Select High-Quality Films and Inks: Use only those specifically intended for the process. This ensures crisp results and lasting adhesion.

- Monitor Curing Times: Adjust exposure based on material and design. This prevents under- or over-curing.

- Always Prep Surfaces: Wipe all target surfaces so they are dust-free and smooth before transfer.

- Run Sample Prints: Test prints before any large-batch order to check adhesion and color quality.

- Store Supplies Properly: Store all inks and films away from heat, direct sunlight, and humidity.

Benefits for Business and Sustainability

This advanced printing system unlocks new creative opportunities for custom products and fast workflow. Less waste and high reliability are built in for every job. Its unique ability to handle both textured and uneven surfaces means you can make premium, tailor-made items easily. Every print supports a polished, professional look—essential for making your goods stand out in any competitive market.

Environmental Considerations in Modern Printing

By using UV-curable inks, this process helps reduce emissions compared to older, solvent-based systems. No water or harsh chemicals are necessary, so you need fewer steps and less energy overall. The process helps keep material waste to a minimum as well, helping companies build a reduced environmental footprint when launching innovative new products.

Trends and Advances in Customization

The printing industry is innovating fast, especially in transfer films and inks. Each improvement allows for even greater speed, brighter shades, and improved sticking power on challenging surfaces. As costs decrease, more companies choose to invest in this technology for high-quality, unique solutions. By adopting UV Transfer, you provide lively, durable products that earn attention and satisfy your customers.