4 products

Heat Press for DTF Transfers: A Complete Guide

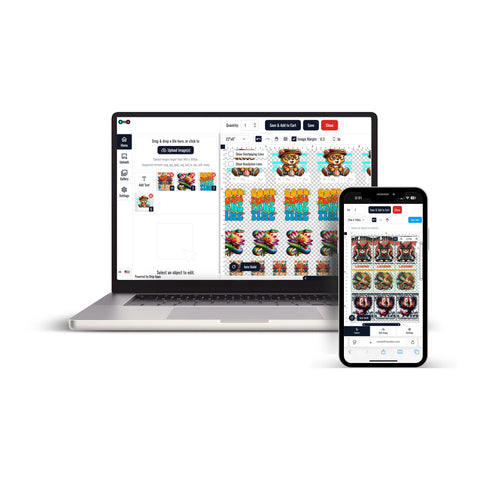

Heat Press for DTF Transfers - DTF (Direct to Film) printing is a fantastic method for custom apparel. Here’s how to use the right heat press for DTF transfers.

Heat Press Machine for DTF Transfer: The Basics

A heat press machine for DTF transfer is crucial for transferring designs onto fabrics. Proper heat settings ensure vibrant and durable prints.

Choose a heat press that offers precise control over temperature, pressure, and time for the best results in DTF printing.

Best Heat Press for DTF Transfer: Choosing the Right One

The best heat press for DTF transfer should have adjustable temperature and pressure settings for consistent results. Look for user-friendly machines.

Reliable brands offer heat press machines that are ideal for various printing projects, providing professional results every time.

DTF Transfer Heat Press Settings: Key Adjustments

DTF transfer heat press settings are crucial for ensuring proper adhesion. Typically, use a temperature of 160-170°C for 15-20 seconds.

Adjust the pressure to medium and ensure even pressure distribution for the best transfer results. Test settings for different materials.

DTF Transfer Heat Press: Step-by-Step Process

For DTF transfers, first set the heat press to the desired temperature, then carefully place the transfer film onto the fabric.

Ensure the correct timing and pressure are applied for the transfer to fully adhere to the fabric without errors or distortions.

Heat Press DTF Transfer: Proper Application

To heat press DTF transfer, place the transfer paper onto the fabric, ensuring it is aligned. Apply even pressure for proper adhesion.

Always test on scrap fabrics first to adjust temperature and pressure settings based on the fabric type and transfer size.

DTF Heat Transfer Ready to Press: Convenience and Efficiency

DTF heat transfer ready to press are pre-printed, making them a time-saving option for mass printing projects.

Simply press the pre-printed transfer sheet onto the fabric using your heat press, making the process fast and efficient for bulk orders.

How to Heat Press DTF Transfer: A Simple Guide

To heat press DTF transfers, place the transfer film on the fabric, set the heat press to the correct settings, and press.

Follow manufacturer instructions for your transfer film and fabric to avoid mistakes and ensure vibrant results. Adjust as necessary.

DTF Heat Transfer Ready to Press: Fast Setup for Printing

DTF heat transfer ready to press designs allow for quick setup and easy printing. Simply align the transfer and press with heat.

This ready-to-press option ensures quicker production, ideal for large-scale operations or quick-turnaround projects.

Heat Press Direct to Film Transfers: Quick and Effective Process

Heat press Direct to Film transfers involves placing the printed transfer film onto the fabric and applying consistent pressure with heat.

Make sure to monitor the temperature and pressure during the process to guarantee proper adhesion and prevent burning.

Heat Press Settings for Direct to Film Transfers: Optimal Results

Heat press settings for Direct to Film transfers should be set around 160-170°C for 15-20 seconds at medium pressure. Fine-tuning is key.

Adjust based on the fabric type and design size to avoid overheating or under-pressing the transfer, which could affect the print quality.

How to Press Direct to Film Transfers with Heat Press: Detailed Steps

To press Direct to Film transfers with a heat press, ensure the transfer film is aligned on the fabric. Apply consistent heat and pressure for proper transfer.

Check the transfer after each press to ensure full adhesion before removing the transfer film from the fabric.

How to Heat Press a DTF Transfer: Step-by-Step Instructions

To heat press a DTF transfer, set the heat press to the recommended temperature, place the transfer film on the fabric, and press.

Once the pressing is complete, allow the fabric to cool before removing the transfer paper for the best results.

DTF Heat Press Transfers: How to Achieve Vibrant Results

Direct to Film heat press transfers require the right temperature, pressure, and time to ensure vibrant, long-lasting prints on fabric.

Be sure to monitor the heat press throughout the process to maintain consistent quality for each transfer.

Heat Press Machines for DTF Printing: What to Look For

When choosing heat press machines for DTF printing, look for features such as adjustable pressure, temperature control, and even heat distribution.

Quality heat presses ensure that your Direct to Film transfers are applied consistently, providing professional results for every print.

How to Use Heat Press for DTF: Tips for Success

To use a heat press for DTF printing, set the correct temperature and pressure, align the transfer, and press it onto the fabric.

Always check the settings based on fabric type and transfer sheet thickness. Use proper heat transfer paper to avoid damage to the print.

Professional Heat Press for DTF Transfer: Why It Matters

A professional heat press for DTF transfer ensures consistent, high-quality results, especially for large-scale production or specialized projects.

Investing in a professional heat press helps streamline the DTF printing process, ensuring that every print is of the highest quality.

Conclusion: Mastering Heat Press for DTF Transfer

Mastering the heat press for DTF transfer is key to achieving vibrant, durable prints. Use the correct settings and equipment for best results.

By following the proper techniques, you can produce professional-quality DTF transfer efficiently and consistently, whether for business or personal use.

Click Here For DTF Transfers Catagory

Vikipedi - DTF