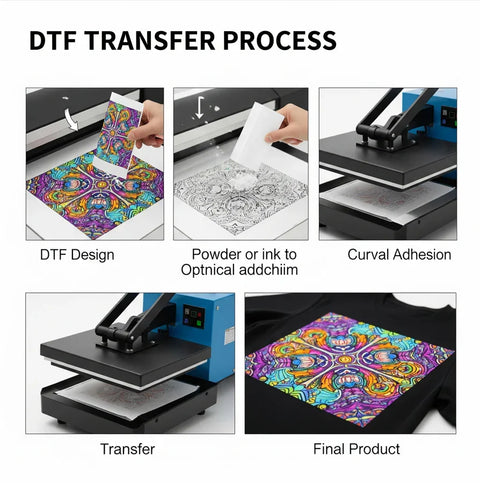

Get Perfect Prints with DTF Transfer Heat Press Settings 🔥👕

DTF Transfer Heat Press Settings are key to achieving sharp and long-lasting results. The right temperature, time, and pressure make all the difference. Without proper settings, designs may peel, fade, or misalign. Beginners and pros alike need to follow exact values for success.

Why Settings Matter in DTF Printing

DTF prints look amazing — but only if applied correctly. Heat press settings control how the design bonds with the fabric. A few seconds too long or too short can ruin the transfer. That’s why precision is essential. Consistent results require accurate control of your press machine.

Ideal Heat Press Temperature

Most DTF transfers work best at 300–320°F (149–160°C). This range allows the adhesive powder to melt and bond properly. If the temperature is too low, the print won’t stick. If it’s too high, the film may warp. Always use a reliable thermometer to check accuracy.

Recommended Time Duration

Pressing time usually falls between 10 to 15 seconds. For most films, 12 seconds is ideal. Longer pressing may burn the fabric or blur the design. Shorter times might not activate the glue completely. Always test before running bulk orders.

Medium to High Pressure

DTF transfers need medium to firm pressure for full adhesion. Too little pressure leaves gaps. Too much may distort the fabric or squeeze out ink. Manual presses need adjustments by hand. Digital presses can be preset for consistent results. A pressure test sheet can help calibrate your machine.

Hot Peel vs. Cold Peel

Peeling timing depends on the type of film.

-

Hot peel: Remove the film immediately after pressing.

-

Cold peel: Let the print cool down fully before peeling.

Check the film instructions to avoid damage. Some universal films allow both methods — test to see what works best.

Pre-Press Your Fabric

Before applying the design, pre-press the fabric for 2–5 seconds. This removes moisture and wrinkles. A smooth surface ensures better bonding. Skipping this step can cause uneven transfer or peeling edges.

Use Teflon or Parchment Paper

Always use a barrier between the film and heat plate. Teflon sheets or parchment paper protect your transfer from direct contact. They also prevent sticking or overheating. Replace them if they become worn or discolored.

Try a Test Print First

Before doing mass production, make a test run. Different fabrics react differently. Cotton, polyester, and blends may each need minor adjustments. Write down your best settings and stick to them for consistency.

Avoid Common Heat Press Mistakes

Here are some issues and how to fix them:

-

Print peels off after washing?

→ Increase pressure or check temperature. -

Design melts or discolors?

→ Lower your heat and reduce pressing time. -

Edges not sticking?

→ Make sure to pre-press and apply even pressure.

Fixing these issues saves time, materials, and frustration.

Clean Your Heat Press Regularly

Ink or residue on the platen affects heat transfer. Clean it weekly with a soft cloth and heat-safe cleaner. Dirty platens cause uneven heat and poor results. A clean press ensures even, smooth applications every time.

Save Your Settings

Once you find the ideal combo of time, temperature, and pressure, save it. Label it for each fabric type. This makes repeat jobs faster and more reliable. Use a notepad, phone app, or tape it directly on your press.

Upgrade Your Equipment If Needed

Old or inconsistent presses lead to poor-quality prints. If your machine can’t maintain stable heat, it’s time for an upgrade. Newer models offer digital control and precise temperature tracking. They also reduce guesswork, making your job easier.

Final Thoughts

DTF Transfer Heat Press Settings perfect prints require more than just good design. They need the right DTF Transfer Heat Press Settings. Time, temperature, and pressure must work together. When done correctly, you get sharp, vibrant, and durable results. Whether you're printing for fun or for business, mastering these settings is key. Don’t guess — press with purpose. Your transfers will thank you. 💪