8 products

Addison DTF Transfer Guide

Addison DTF Transfer offers a reliable way to produce vibrant, durable designs on various materials. This printing method suits both personal projects and professional production. It delivers consistent results with strong color accuracy. Using specialized printers and controlled heat, designs transfer cleanly onto fabric. These prints last through repeated use and washing.

This technology has grown popular in custom apparel production. It balances flexibility, efficiency, and visual quality. Addison DTF Transfer enables creators and businesses to produce professional-looking designs. This method overcomes limitations found in traditional printing.

What Is Direct to Film Printing?

Direct to Film printing involves printing designs onto special PET film instead of fabric directly. After printing, an adhesive powder is applied, and the design is cured. Finally, heat transfers the design onto the final surface.

This process produces sharp, long-lasting results on fabric types such as cotton, polyester, and blends. Because the design sits evenly on the fabric surface, the print remains flexible and detailed. It resists cracking, making it ideal for custom apparel, promotional items, and small-batch production.

Essential Equipment for Quality Results

Using the right equipment is critical for professional outcomes. Reliable tools ensure accurate color reproduction, consistent pressure, and even heat distribution throughout the process. This enhances print quality and helps maintain standards.

Printers and Heat Press Machines for Addison DTF Transfer

High-quality printers handle specialized inks and film, producing clean, vibrant designs. A dependable heat press bonds the design to fabric, ensuring durability and uniform adhesion. These machines maintain print consistency across multiple pieces. This consistency is especially important for businesses.

Supporting Materials and Supplies

Besides machinery, the process requires PET films, adhesive powders, and compatible inks. These materials work together smoothly, reducing errors and improving efficiency. Using quality supplies also ensures prints remain intact after washing and regular wear.

Custom Printing for Shirts

This printing method is widely used for custom shirts. It performs well on various fabric types, from lightweight t-shirts to thicker hoodies. Designs retain color strength and detail across different textiles.

The workflow prints the design onto film, cures it, and presses it onto the shirt. This process creates clean edges and smooth textures, delivering professional-quality finishes. It's practical for both individual creators and businesses making branded apparel.

Importance of Transfer Film Quality

Transfer film quality strongly affects print clarity and durability. High-quality film allows designs to release cleanly during heat application, preventing peeling or distortion. It maintains color and detail consistency over time.

Selecting film matching your printer and fabric type is essential. The right pairing ensures reliable transfers and reduces waste. This combination makes production more efficient and cost-effective.

How the Printing Process Works

The printing process relies on heat and pressure to transfer ink from film to fabric. After transfer, the design remains flexible and durable. It maintains its appearance even after many washes.

This method creates vivid, fade-resistant prints without sacrificing comfort. Finished garments stay soft and wearable while showcasing bold, detailed designs. This makes the method ideal for everyday wear and commercial products.

Where to Purchase Supplies

Supplies for this printing method come from both online and local retailers. Choosing reputable suppliers maintains consistent quality and avoids compatibility issues.

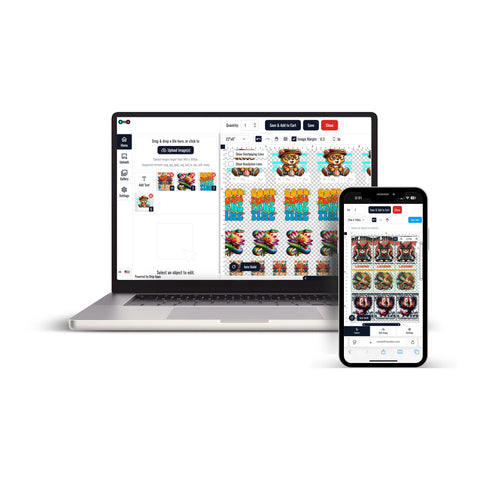

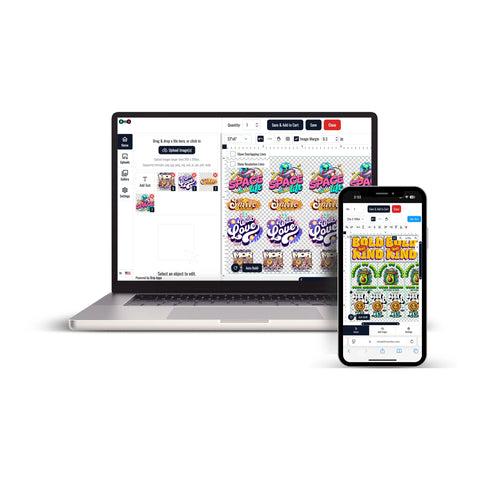

Online Purchasing Options

Online stores provide convenience, broad product selection, and easy comparison of materials. Customers can upload designs, review specifications, and place orders from anywhere. This option suits ongoing production or bulk orders well.

Local Suppliers

Local providers offer faster turnaround and sample inspection before purchase. This helps with urgent projects or testing new materials. Nearby suppliers also provide personalized support, improving the buying experience.

Balancing Cost and Quality

Affordable options exist through bulk purchasing and supplier discounts. Managing costs is important but quality must remain a priority. Durable materials and reliable prints enhance customer satisfaction and reduce rework.

Investing in dependable supplies results in better long-term value. It minimizes defects and ensures consistent production results.

Achieving the Best Results with Addison DTF Transfer

High-quality transfers relies on premium materials and proper application. Prints resist fading, cracking, and peeling to maintain their appearance over time. This adds perceived value to the final product.

By using trusted equipment, compatible supplies, and proven techniques, creators and businesses achieve consistent professional results. This printing method offers a dependable solution for custom apparel that meets modern quality expectations.

Follow our Addison-based printing projects on Instagram and Facebook for local updates and custom work examples.