7 products

A Comprehensive Guide to DTF Transfer

DTF Transfer has evolved rapidly, and one of the most flexible solutions available today is Direct-to-Film technology. This method allows businesses and creators to produce high-quality custom designs with excellent durability and color accuracy. From clothing decoration to UV-based applications on hard surfaces, this printing approach has become a reliable choice for professionals and beginners alike.

What Is DTF Transfer?

DTF Transfer is a production method where artwork is printed onto a transparent PET film and later transferred onto a surface using heat and adhesive powder. Unlike traditional techniques, it does not require cutting, weeding, or fabric-specific limitations.

This process delivers sharp details and vibrant colors on materials such as cotton, polyester, blended fabrics, and selected non-textile surfaces when UV curing is used.

How the Process Works

Design Setup

Artwork is prepared using design software to ensure accurate sizing, resolution, and color balance before printing.

Film Printing

The design is printed onto PET film using specialized inks. A white ink layer is added to maintain color clarity on light and dark surfaces.

Adhesive Layer

While the ink is still wet, a fine adhesive powder is applied. This layer enables the design to bond properly during application.

Curing Stage

Heat is used to melt the powder, preparing the film for pressing.

Final Application

A heat press transfers the design from film to the chosen surface, resulting in a clean and durable finish.

Size Options

Transfers are available in different dimensions, making them suitable for a wide range of projects.

-

Small formats are ideal for logos, chest prints, and accessories

-

Medium formats work well for shirts, hoodies, and tote bags

-

Large formats are commonly used for back prints, jackets, and oversized graphics

Choosing the correct size improves visual balance and helps reduce material waste.

UV-Based Film Transfers

UV-based film transfers are designed specifically for solid, non-porous materials. Instead of heat, ultraviolet light cures the ink, creating a strong and lasting bond.

Popular Applications

-

Drinkware and tumblers

-

Phone cases and tech accessories

-

Promotional items and signage

This method is valued for its smooth texture, scratch resistance, and professional appearance.

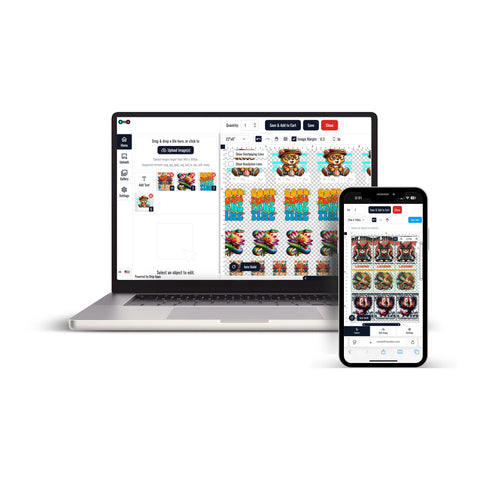

Custom Design Solutions

Custom film transfers offer complete creative freedom. Designs can be adjusted by size, color, and layout to match branding goals or personal preferences.

They are commonly used for:

-

Company branding

-

Team and staff apparel

-

Personalized gifts

-

Event and promotional merchandise

Custom solutions ensure consistency and easy repeat production for growing businesses.

Transfer Sheets Explained

What Are They?

Transfer sheets are pre-printed films that contain one or multiple designs, ready for application. They are often used for bulk orders or repeated layouts.

Key Benefits

-

Faster workflow

-

Lower cost per unit

-

Efficient use of film space

-

Ideal for repeated designs

Gang sheets are especially useful when handling multiple graphics in a single order.

Printing Equipment

Specialized printers are required to produce high-quality film transfers. These machines support layered ink printing and precise color output.

Important Features

-

White ink capability

-

High-resolution printing

-

Software compatibility for layout control

Quality equipment plays a major role in the final durability and appearance of the print.

Ready-to-Press Transfers

Ready-to-press options arrive fully prepared and only require a heat press. They are ideal for businesses that want professional results without managing the printing process.

Advantages

-

Saves production time

-

Easy to apply

-

Consistent results

-

Suitable for high-volume orders

Finding Local or Online Services

These transfer solutions are available through local print shops and online suppliers. Many providers offer fast shipping, custom sizing, and bulk pricing, making access easy regardless of location.

Best Use Cases

This printing method is ideal for projects that demand flexibility, durability, and strong visual impact. Common uses include apparel, accessories, promotional products, and hard-surface applications using UV curing.

Final Thoughts

Film-based transfer technology provides a reliable and creative solution for modern printing needs. Whether producing custom apparel or decorating hard surfaces, it offers consistency, efficiency, and professional results.

For inspiration, updates, and real-world examples, follow Ohio DTF Transfer on social media:

👉 https://www.tiktok.com/@ohiodtftransfer

👉 https://www.instagram.com/dtftransferohio/

👉 https://www.facebook.com/dtftransferohio/