5 products

DTF Transfer For Jacket

DTF Transfer For Jacket is a reliable and modern solution for creating custom jackets with strong visual impact. This method allows detailed, full-color designs to be applied to many fabric types while maintaining durability and flexibility. For brands, creators, and small businesses, it offers a professional finish without complex setup or high production costs.

Custom jackets produced with DTF printing stand out thanks to sharp details and smooth texture. From minimalist logos to bold artwork, the results remain consistent even after repeated use.

Why Choose DTF Transfer For Jacket?

DTF Transfer For Jacket works by transferring designs from a special film onto fabric using heat and pressure. This process ensures excellent color accuracy and strong adhesion. Unlike traditional methods, it does not limit design size or color count, making it ideal for creative freedom.

Another advantage is its adaptability. DTF works well on both lightweight and heavy jackets, offering flexibility for fashion, workwear, and promotional products.

Key Benefits

-

Full-color, high-resolution prints

-

Soft and flexible finish

-

Long-lasting wash resistance

-

Suitable for small or bulk orders

These benefits make DTF a practical option for both startups and established apparel brands.

Jacket Design Options

DTF printing supports a wide range of design styles. Simple chest logos, back prints, sleeve details, or large graphics can all be applied with consistent quality. Special film options also allow unique visual effects without altering the main production process.

Depending on the jacket fabric and design goal, different transfer finishes can be selected to enhance the final appearance.

Popular Effects

-

Standard matte or semi-gloss

-

Metallic or reflective accents

-

Glow or textured finishes

These options help brands differentiate their jackets in competitive markets.

Application Process

The DTF process for jackets is straightforward but requires precision. Designs are first printed onto film, coated with adhesive powder, and cured. Once ready, the transfer is applied to the jacket using a heat press.

Pre-pressing the jacket is essential. Removing moisture and wrinkles ensures strong bonding and a smooth final result. Proper temperature and pressure settings are key to durability.

Basic Steps

-

Prepare and mirror the artwork

-

Print on transfer film

-

Apply and cure adhesive powder

-

Heat press onto the jacket

-

Peel according to instructions

-

Finish with a second press

When done correctly, the print integrates smoothly with the fabric.

Fabric Compatibility

One of the strongest features of DTF printing is its fabric versatility. It adheres well to many materials commonly used in jackets.

Compatible fabrics include cotton, polyester, blends, and certain synthetic materials. This makes it suitable for casual wear, uniforms, sportswear, and outerwear collections.

Testing is always recommended for specialty fabrics, especially those with water-resistant coatings.

Durability and Performance

DTF prints are designed to withstand regular wear. Jackets often face friction, movement, and environmental exposure, and DTF performs well under these conditions. The print remains flexible and resists cracking or fading when proper care instructions are followed.

This durability makes DTF ideal for daily-use jackets and long-term branding projects.

Ideal for Businesses

For businesses, DTF printing offers scalability. You can produce single custom pieces or expand to bulk orders without changing equipment or workflow. This flexibility supports seasonal collections, limited drops, or ongoing uniform production.

Low setup requirements also reduce upfront costs, making it accessible for new brands.

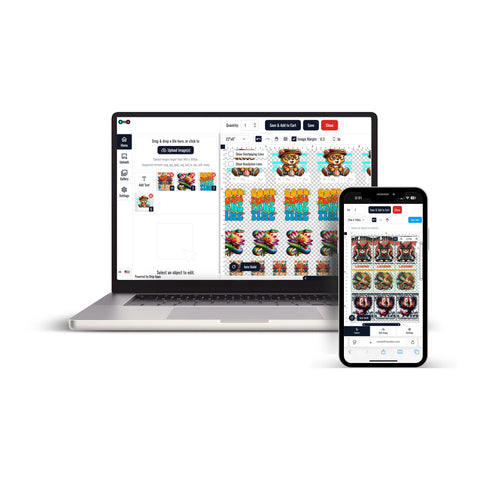

Local and Online Services

DTF printing services are available both locally and online. Local providers may offer faster turnaround and direct communication, while online services provide convenience and broader customization options.

Choosing a reliable provider ensures consistent quality, accurate color matching, and dependable delivery.

Final Thoughts

DTF printing is a practical and high-quality solution for custom jacket production. It combines design freedom, durability, and cost efficiency into one modern printing method. Whether for fashion, branding, or promotional use, it delivers professional results with minimal limitations.

For real examples, tips, and updates, follow Ohio DTF Transfer on social media:

👉 https://www.tiktok.com/@ohiodtftransfer

👉 https://www.instagram.com/dtftransferohio/

👉 https://www.facebook.com/dtftransferohio/