5 products

DTF Transfer Instructions

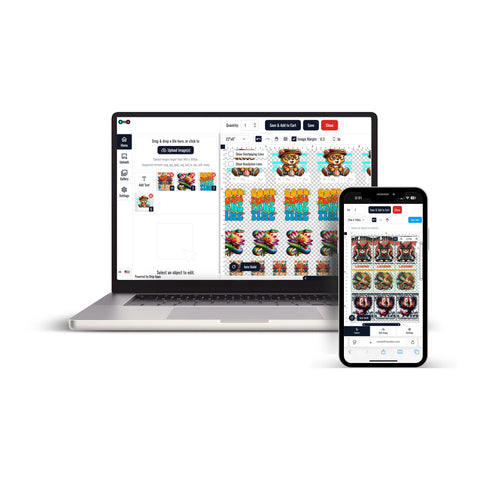

DTF Transfer Instructions have become one of the most reliable solutions for custom apparel printing. Known for vibrant colors and long-lasting results, this method works well on many fabric types. Following the correct pressing and care instructions is essential to achieve professional-quality prints that last through repeated use and washing.

This guide explains the full process clearly, from preparation to aftercare.

What Is DTF Transfer Instructions?

DTF Transfer Instructions is a process where designs are printed onto a special coated film and then transferred onto fabric using heat and pressure. Printing on film first allows for sharp details, smooth color transitions, and strong adhesion.

This method is widely used for t-shirts, hoodies, bags, and other fabric products.

Preparing the Transfer

Before pressing, proper preparation ensures clean and durable results.

Design Setup

Artwork should be mirrored before printing so it appears correctly after transfer. High-resolution files produce sharper prints, especially for text and detailed graphics.

Printing and Powder

Once printed on the film, adhesive powder is applied while the ink is still wet. The excess powder is shaken off, leaving a clean coated design ready for curing.

Curing the Film

Curing activates the adhesive and prepares the transfer for pressing. This step is done using heat until the powder melts evenly without burning.

Heat Press Setup

Correct heat press settings are crucial for success.

Temperature and Time

Most transfers apply well at around 320°F (160°C) for 10–15 seconds. Timing may vary depending on fabric thickness and film type.

Pressure

Medium pressure is recommended. Too much pressure can distort the design, while too little may cause poor adhesion.

Pre-Pressing

Always pre-press the garment for a few seconds to remove moisture and wrinkles. This creates a smooth surface for better bonding.

Applying the Transfer

Place the cured film onto the garment in the desired position. Make sure it lies flat and is properly aligned. Press using consistent heat and pressure.

After pressing, peel the film according to the manufacturer’s instructions. Some films require hot peeling, while others need to cool before removal. A second short press with a protective sheet can improve durability and softness.

Washing and Care

Proper care extends the life of the print.

Washing Guidelines

Wash garments inside out using cold water. This reduces friction and protects the print surface.

Drying Tips

Air drying is best. If using a dryer, choose low heat. High temperatures can weaken adhesion over time.

What to Avoid

Do not use bleach or fabric softeners. Avoid ironing directly on the print area, as heat can damage the design.

Fabric Compatibility

This method works on many materials, including cotton, polyester, and blended fabrics. It also performs well on both light and dark garments, unlike some traditional printing methods.

Testing on a sample fabric is always recommended before full production.

Common Mistakes to Avoid

Small errors can affect final quality.

Issues to Watch For

-

Incorrect temperature settings

-

Uneven pressure

-

Skipping the curing step

-

Pressing on damp fabric

-

Rushing peeling

Avoiding these mistakes helps ensure clean, long-lasting results.

Best Practices

Consistency is key when producing multiple items.

Helpful Tips

-

Keep press settings consistent

-

Test one sample before bulk runs

-

Store transfers in a cool, dry place

-

Use quality film and adhesive

Following these steps improves reliability and reduces wasted materials.

Final Thoughts

DTF transfers offer a flexible and durable solution for custom printing. With correct pressing, washing, and care practices, designs remain vibrant and professional over time. Whether you are new to printing or managing production, following proper instructions makes a noticeable difference.

For tutorials, real examples, and updates, follow Ohio DTF Transfer:

👉 https://www.tiktok.com/@ohiodtftransfer

👉 https://www.instagram.com/dtftransferohio/

👉 https://www.facebook.com/dtftransferohio/