7 products

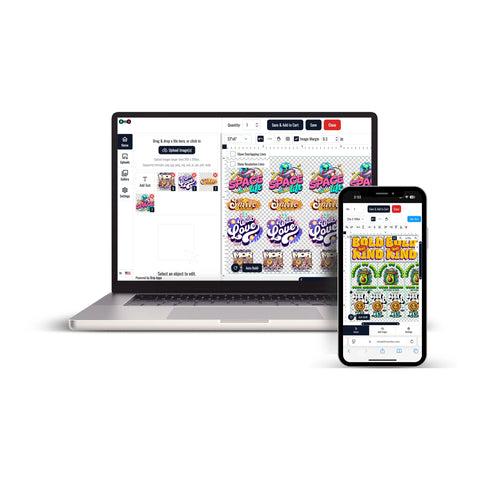

The Ultimate Guide for Custom Cups

UV DTF Cup Wraps - UV DTF cup wraps are custom wraps printed using Direct-to-Film (DTF) technology.

These wraps are applied to cups using UV printing for vibrant designs.

The process involves printing onto transfer film, then applying it to the cup.

UV DTF printing ensures that designs are durable, vivid, and long-lasting.

UV DTF Cup Wrap Printer: Essential for Custom Printing

A UV DTF cup wrap printer is designed specifically for printing on cup surfaces.

It uses UV light to cure the ink, ensuring quick drying and vibrant colors.

UV DTF printers are ideal for custom cup printing in bulk.

These printers can print directly onto the wrap or transfer film.

They’re widely used in businesses that specialize in custom drinkware.

How to Make UV DTF Cup Wrap

Making UV Direct to Film cup wraps involves printing your design onto special transfer film.

Once the design is printed, it is carefully applied to the cup using heat and pressure.

Ensure that your design is of high resolution for clear, vibrant prints.

Use the right type of transfer film and ensure it fits your cup size.

The UV DTF method guarantees long-lasting designs that won’t fade or peel.

How to Apply UV DTF Cup Wrap

To apply UV DTF cup wraps, first print the design onto transfer film.

Use a heat press machine to transfer the design onto the cup.

Ensure that the cup is clean and properly aligned before applying the wrap.

Press at the correct temperature and pressure for the best results.

Once applied, the design is vibrant, durable, and ready for use.

Custom UV DTF Cup Wrap: Personalize Your Drinkware

Custom UV DTF cup wraps allow you to personalize drinkware for businesses, events, or gifts.

You can create unique, one-of-a-kind designs for mugs, tumblers, and other cups.

These wraps offer unlimited design options, from logos to detailed artwork.

Custom UV DTF cup wraps are perfect for creating branded merchandise or personalized gifts.

Whether it’s for promotional items or special occasions, UV DTF wraps offer high-quality prints.

UV DTF Wraps for Cups: Advantages of This Printing Method

UV DTF wraps for cups offer many advantages, including vibrant color reproduction and durability.

Unlike traditional methods, UV DTF does not require multiple setup steps.

The prints are more flexible, preventing cracking or peeling over time.

UV DTF printing works well on both curved and flat surfaces.

This method also offers faster production times, making it ideal for bulk printing.

UV DTF Cups Wraps Wholesale Suppliers

UV Direct to Film cup wraps wholesale suppliers provide businesses with cost-effective options for bulk printing.

Many suppliers offer custom-sized wraps, perfect for different types of cups.

Buying wholesale can significantly reduce costs for businesses that need large quantities of custom cups.

Look for suppliers that use high-quality UV DTF printers for the best results.

Choose suppliers with fast turnaround times and reliable shipping services.

UV Direct to Film Printer for Cup Wraps: What to Look For

When buying a UV Direct to Film printer for cup wraps, look for one with high resolution and quick curing.

The printer should be compatible with various cup sizes and materials.

Ensure the printer can handle high volumes and offers consistent print quality.

UV DTF printers with adjustable settings are ideal for achieving precise designs.

Check that the printer supports various transfer films for diverse designs.

Direct to Film Cup Wraps How to Make: Step-by-Step Guide

Making DTF cup wraps requires printing your design on transfer film first.

Use a UV DTF printer to ensure that your design has vibrant colors.

Apply the transfer film to the cup using a heat press or specialized machine.

Make sure to align the wrap properly to avoid design misplacement.

Once the design is transferred, the cup is ready for use.

What Is UV Direct to Film Cup Wraps?

UV Direct to Film cup wraps are custom prints that are transferred to cups using Direct-to-Film technology and UV curing.

This printing method produces durable, high-quality designs that are resistant to wear and fading.

Ideal for creating personalized and custom drinkware for events, businesses, and gifts.

UV DTF prints are versatile and work well on a variety of cup types.

The process ensures vibrant, long-lasting designs that maintain their quality over time.

How to Print UV Direct to Film Cup Wraps

To print UV Direct to Film cup wraps, first, design your artwork in a digital format.

Next, print the design onto transfer film using a UV DTF printer.

Ensure the printer uses high-quality inks for vibrant, durable results.

After printing, use a heat press to apply the design to the cup.

The result is a durable, vibrant print that will last through regular use.

Click Here For UV DTF Transfers Catagory

Vikipedi - DTF